Maximise your efficiency with precise material data evaluation

Discover the full potential of your material data and optimise your processes with PRODUCT INTELLIGENCE. Our system enables the precise evaluation of all material and product data, identifies cost eaters and cost drivers as well as preferred parts in a dynamic way. By intelligently analysing materials, individual parts, sub-assemblies and products, it recognises the interwoven network of all connections, taking into account references, assemblies, frequencies and current prices. At the same time, it detects duplicates and uses KPIs to determine the value of part utilisation, which you can control.

Cost reduction and control: utilise the full potential of your material data

Find out how PRODUCT INTELLIGENCE can increase your efficiency and get started on a cost-effective future today. This demonstrably reduces costs, quickly and sustainably. KPIs are used to determine the value of parts utilisation and are controlled by you. Our intelligent analysis not only identifies cost guzzlers and cost drivers, but also preferred parts in a dynamic way. Discover the full potential of your material data and optimise your processes with PRODUCT INTELLIGENCE.

Evaluate the material and product structure

In the TOP-DOWN view you can see the entire product structure including further sub-assemblies down to any depth. It does not matter whether you manage your data in a PDM system or have stored them on a file server. SIMILIA PRODUCT INTELLIGENCE is able to recognize and display the product structure based on the CAD data.

Structure BOMs can be easily created and exported (e.g. to Excel). The BOM is also supplemented with existing attributes that are available from the ERP system.

Evaluating references and shoring

Within seconds, you can see in which other assemblies and in which number the individual parts and components are directly installed. Via this BOTTOM-UP-VIEW you can immediately see how strongly the items or assemblies are integrated or installed in higher-level assemblies and products. The frequencies are recorded immediately. This allocation is updated dynamically.

Cross connections to similar materials

The advantages of the geometric similarity search become particularly clear in this way. This function can be applied to any dataset at any time. Thereby you extend the possibilities to reduce your material costs. You immediately recognize the cross connections to other similar and very similar materials. By evaluating the KPI values, you can decide whether, for example, material A should be replaced by material B because material B has a higher degree of cross-linking. In this way, you reduce costs. You make the best possible use of resources. You increase your competitiveness. You become more successful. You become more profitable.

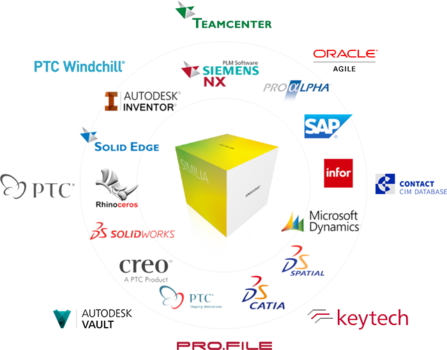

System-independent connector technology for CAD, PDM, PLM & ERP

SIMILIA can be integrated into almost any IT system landscape. The heterogeneity of the structures that have grown up in the company is irrelevant. This is particularly common in medium-sized companies.

SIMILIA is installed and commissioned at a fixed price based on a standardized process flow. The costs are clearly and transparently quantified. No "ifs and buts". The system can be subsequently configured by the customer. Using this technology, the operation of SIMILIA is permanently robust. We thus guarantee continuous operation. Your data remains in your company, SIMILIA is not a cloud.

![[Translate to English:] Baugruppenstruktur in SIMILIA PRODUCT INTELLIGENCE [Translate to English:] Baugruppenstruktur in SIMILIA PRODUCT INTELLIGENCE](/fileadmin/_processed_/7/7/csm_SIMILIA-45_PI-Baugruppenstruktur_01_a53c5e72b3.png)

![[Translate to English:] Referenzen und Verbauungen in SIMILIA PRODUCT INTELLIGENCE [Translate to English:] Referenzen und Verbauungen in SIMILIA PRODUCT INTELLIGENCE](/fileadmin/_processed_/d/0/csm_SIMILIA-45_PI-REFstruktur_01_2fd324080f.png)

![[Translate to English:] Ähnliche Artikel sehen - CROSS-VIEW [Translate to English:] Ähnliche Artikel sehen - CROSS-VIEW](/fileadmin/_processed_/f/7/csm_SIMILIA-45_PI-Dubletten_01_33616e5a98.png)